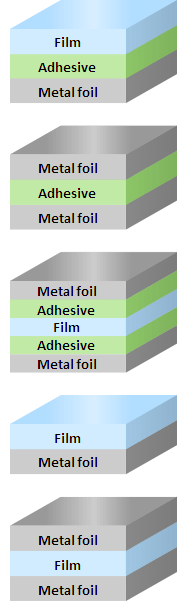

The metal foil and the plastic film is bonded by adhesive(dry lamination) or by heat melting(thermal lamination). Laminate is also possible for three or more layers upon request.

| Elastic modulus control | Follow-up / curl control to the substrate expansion and contraction |

|---|---|

| Chemical resistance | Etch resistance |

| Adhesive force control | Ensure the adhesive force between the various metal foil / plastic film |

| Functionality grant | Rust function / antistatic |

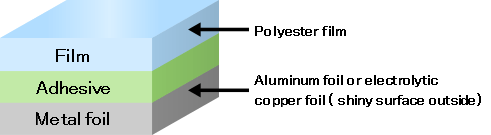

Bonding product of aluminum foil or electrolytic copper foil with polyester film by adhesive in-between.

Have been used in the field required such as electromagnetic shielding by its electrical characteristics.

| Al-PET | Cu/PET | ||||

|---|---|---|---|---|---|

| Part number | 12-50 | 20-75 | 30-12 | 18-25 | 35-50 |

| Metal foil | Aluminum foil | Electrolytic copper foil | |||

| Metal foil thickness(μm) | 12 | 20 | 30 | 18 | 35 |

| Adhesive layer thickness(μm) | 2~3 | 20 | |||

| PET film thickness(μm) | 50 | 75 | 12 | 25 | 50 |