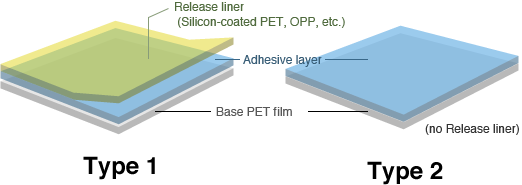

It is utilized in a wide range of fields for surface protection, support, carrier films etc., and applied onto displays, prints, and flexible printed circuit boards (FPCs). We have over 10 variations of adhesive film ensuring sustainable peeling quality on different materials.

High resistance to heat (suitable for high temperature processing such as FPC manufacturing)

Excellent protection performance (strong resistance to cutting, punching, bending, etc.)

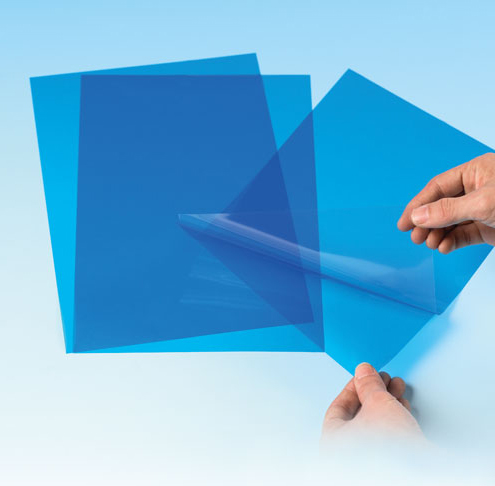

High degree of transparency (practical for processing optical components in need of transparency and contamination protection)

Less sticky residue without contamination of underlying materials

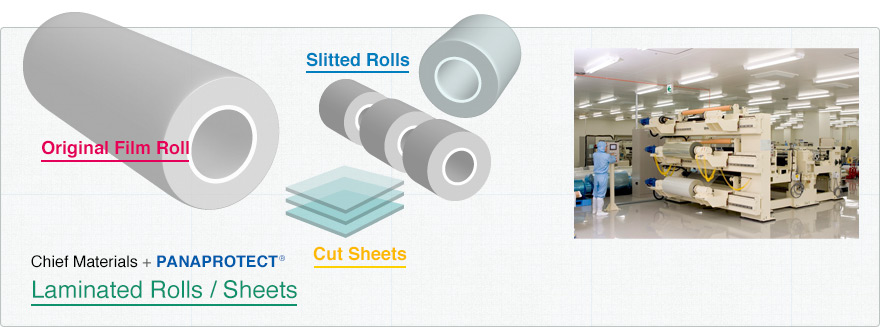

Enables a diverse range of combinations among different types of film, thicknesses, rear coating, and more.

A protective film that resists heat yet provides low film removal force even after heat treatment of protected prints and moldings.

High-transparency film that protects from scratches and stains without leaving residue on optical film or optical glass.

Carrier film when converting film and foam etc., by making use of its re-detachment and anti-staining qualities.

| HP CT |

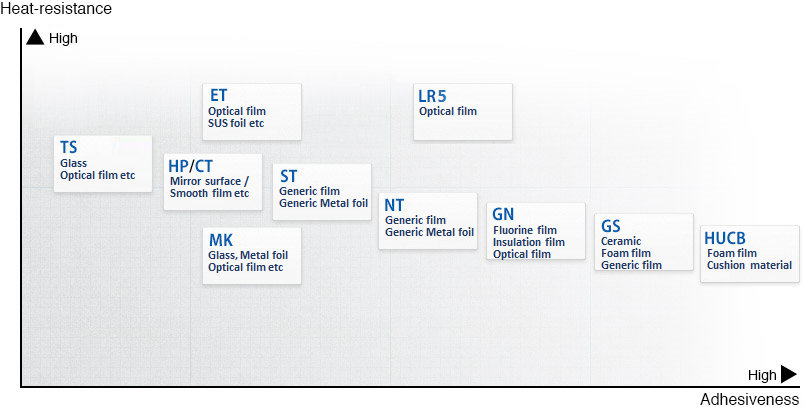

TS | ET | MK | ST | NT | LR5 | GN | GS | HUCB | |

|---|---|---|---|---|---|---|---|---|---|---|

| Base material thickness (μm) Line-up |

25 38 50 75 |

25 | 50 | 38 | 38 50 75 |

38 50 75 |

38 | 38 75 |

38 75 |

100 |

| Adhesive strength PET N/Cm | 0.02 | 0.02 | 0.03 | 0.03 | 0.04 | 0.07 | 0.09 | 0.19 | 0.49 | 1.55 |