We produce new functional films by laminating plastic film to metal foil or with a special process such as resin melting and first-surface decoration. We match customer needs through our high technology, joining even difficult-to-adhere materials to each other.

PANAC provides both dry lamination via traditional adhesives and thermal lamination via heat melting of the film surface.

By laminating two or more layers of film or foil it is possible to take advantage of the characteristics of each material and achieve performance that the materials alone cannot generate.

In addition, we melt resins and coat them directly to materials or combine this with special processing such as surface embossing. We create optimal products and processing processes that meet customer needs.

<Adoption track records>

Shielding parts, damping parts, backlight parts, FPC, medical parts, electronic parts or materials, etc.

Developed our facilities so we can freely customize the process method up to customers’ need or material.

To part specifications’ change associated with market change, or to new needs, responding to flexible and speedy prototype・production. ⇒Thermal lamination, resin coating, embossment, surface treatment etc.

Among various machine rolls, we select the roll that suits the processing need. If the processing is unsuitable with an existing roll we will design a new roll for production.

⇒Processing temperature Max 400℃, surface decoration (embossment) roll, surface special processing roll etc.

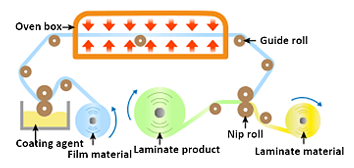

This process applies adhesive on the plastic film that will be laminated. After the adhesive dried the film is press-bonded to its mating film.

Different materials such as plastic film and metal foil can be bonded together in this manner.

| Processing specification | Coating section cleanness | class 1000, 10000 |

|---|---|---|

| Material width limit | max 1700mm | |

| Material type | Various plastic films, metal foil | |

| Adhesive coating thickness (Dry) | 0.1μm – 100μm ※2 heads continuous coating is possible ( undercoating + coating ) |

|

| Characteristic |

|

|

| Materials laminated in the past |

Various polymer films: engineering plastics (PET, PEN, PI, PPE, etc.), olefin film (PE, OPP, TPX, etc.), PMMA, TAC, other plastic films Various foils: SUS foil (12 – 100μm), Cu foil (12 – 70μm), Al foil (9 – 200μm), Ti foil, Fe foil, etc. |

|

| Adhesive |

We can formulate adhesives with various properties as listed to meet customer’s requirements and applications. |

|

| Manufacturing process |

|

|

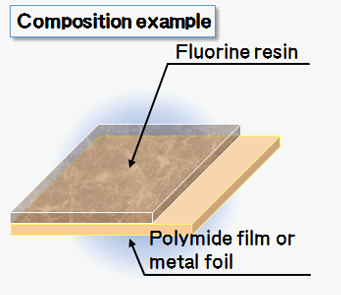

| Composite configuration example |

Metal foil / PET composite product , olefin / PET composite product , metal foil / metal foil composite product |

|

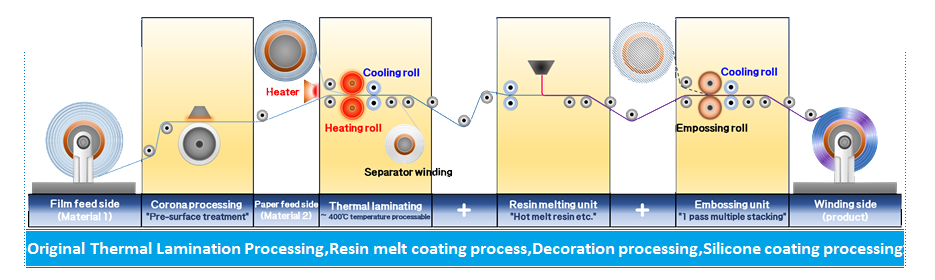

Without using conventional adhesive plastic films may be laminated material such as a plastic film is melted by heat, and bonded by pressure bonding processing. Materials that could not be bonded by dry lamination can also be processed.

As the laminated product does not have an adhesive layer, it can exert the inherent properties of the material (heat resistance, etc.).

| Processing specification | Laminating unit cleanliness | Class 10000 |

|---|---|---|

| Material width limit | max 1400mm | |

| Material types | Various engineering plastics (PET, PEN, PI, PPE, fluorine film, etc.) , olefin-based film SUS foil (10 – 100μm), Cu foil (12 – 70μm), Al foil (9 – 200μm), Ti foil , Fe foil etc. Hot melt sheet , fabric sheet, etc. |

|

| Heating temperature | max 400℃ | |

| Characteristic |

3 or 4 layer lamination is possible. 5+ layer lamination is available upon request. Lamination of high heat-resistant film is also available due to the capability of high processing temperatures (max 400℃). |

|

| Materials tried in the past |

Polymer films: Various engineering plastics, olefin film, fluorine film, LCP film, glass cloth, etc. Metal foils: SUS, Cu, Al, Ti, etc. |

|

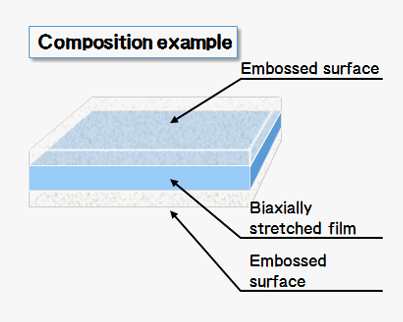

| Composite configuration example |

Metal foil / plastic film composite laminate (SUS / thermoplastic PI, SUS / PEN, etc.) |

|

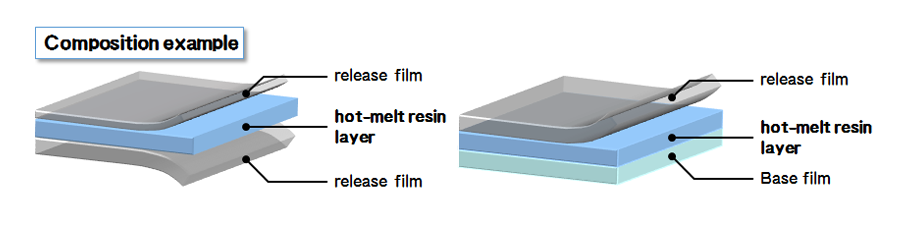

We can carry out lamination processing such as metal-and-resin and

resin-and-resin, which could not be done with the usual lamination technology.

Coats or bonds directly to the material while melting the hot-melt resin.

Laminated products, single-layer products, compound products and so on are available.

Embossing on the film surface

(Single-sided and double-sided simultaneous processing is possible)