We offer specialized punch processing. The punch sizes, shapes and locations are specified according to the customer’s application. All processing is done in a cleanroom.

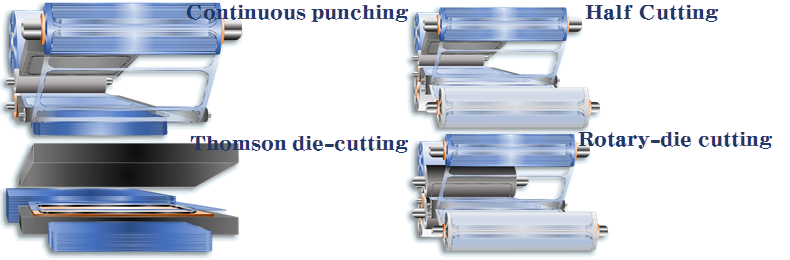

Various punching processing such as automatic continuous punching, rotary die cutting, Thomson punching, etc. are possible at our factory.

Punch tooling is designed by Panac.

We have a variety of highly capable product inspection systems and facilities.

Thomson punching supports large size-sheets (at a subcontractor).

Roll Thomson punching can automatically remove unnecessary parts during the punching process.

A half punching process can wind up the carrier (product) to the core while laminating protective film, a rotary die cutter is suitable for mass production because the drawing die rotates.

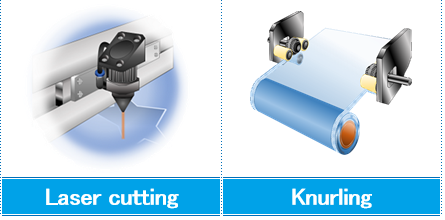

Other processing methods such as laminate cutting can be combined.

Laser cut processing permits us to convert thick plastic sheet, acrylic plate, etc. into a free shape. With edge knurling both edges of film are slightly thickened so as to prevent surface deterioration and blocking of the film during roll winding.

To respond to customer requests, we will work on new processing technology.

All processing is done in cleanrooms

(Class 10,000 or Class 1,000).

We respond to customer requests from large lots to small lots with our flexible production system.

We deliver high-quality products through in-house integrated production and processing and through one-stop solutions.