We propose new functional film by lamination of plastic film and metal foil, or with thermal lamination and other surface coating,

We can match customer’s needs by our high technology even the materials are in difficult composition.,/p>

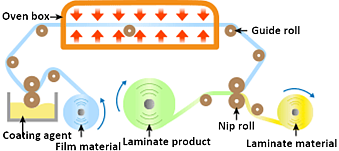

PANAC provides both Dry Lamination by laminating materials with adhesive and Thermal Lamination by heat melting on the film surface.

By laminating two or more layers of film or foils, utilizing the characteristics of each material, it is possible to exert the performance which can not be responsible by itself.

In addition, we melt resins and coat them to materials, or combine special processing such as surface embossing, we propose optimum products and processing processes that meet customer needs.

Shielding parts, damping parts, backlight parts·FPC·medical parts and electronic parts or materials, etc.

The process can apply adhesive to plastic films, and bond it to the other films after dried.

Different materials can be bonded together such as plastic film and metal foil.

| Processing specification | Coating section cleanness | class 1000、10000 |

|---|---|---|

| Use material width | max 1700mm | |

| Use material type | Various plastic films , metal foil | |

| Adhesive coating thickness(Dry) | 0.1μm~100μm ※2 heads continuous coating is possible ( undercoating + coating ) |

|

| Characteristic |

|

|

| Material usage records | Various engineering plastics (PET, PEN, PI, PPE , etc.) , olefin film (PE, OPP, TPX , etc. ), PMMA, TAC, other plastic SUS foil (12 ~ 100μm), Cu foil (12 ~ 70μm), Al foil (9 ~ 200μm), Ti foil , Fe foil etc. | |

| Adhesive | We can design adhesives to meet customer’s requirements and applications. Modulus control (Curl tracking and control the stretch of the substrate) Chemical resistance (etching resistance) Adhesive force control (ensure the adhesive force between various materials) Functionality grant (rust prevention, antistatic etc.) |

|

| Working process |  |

|

| Composite configuration example | Metal foil / PET composite product , olefin / PET composite product , metal foil / metal foil composite product | |

Without using any adhesive, melt the material such as a plastic film by heat, and bond by pressure bonding process. Materials that could not be boned by dry lamination can also be processed.

Since the laminated product without adhesive layer, able to exert a material inherent properties (heat resistance, etc.).

| Processing specification | Coating section cleanness | class 10000 |

|---|---|---|

| Use material width | max 1400mm | |

| Use material type | Various engineering plastics (PET, PEN, PI, PPE, fluorine film, etc.) , olefin-based film SUS foil (10 ~ 100μm), Cu foil (12 ~ 70μm), Al foil (9 ~ 200μm), Ti foil , Fe foil etc. Hot melt sheet , fabric sheet, etc. | |

| Characteristic | 3 or 4 layers lamination is possible . (5 layers or more also available upon request) Lamination of high heat-resistant film is available due to the capable of high processing temperatures(max400℃). Lamination also available for adhesive sheet by heat-melting. It is also possible to laminate such as fabric materials with unevenness by unique press method and melting at high temperature and embedding. |

|

| Material use performance | Various engineering plastics , olefin film , fluorine film , LCP film , glass cloth , etc. Metal foils , SUS, Cu, Al, Ti , etc. |

|

| Composite configuration example | Metal foil / plastic film composite article (SUS / thermoplastic PI, SUS / PEN , etc.) High heat-resistance film composite products (PI / fluorine film ) Multilayer products ( olefin-based film / fluorine film / olefin-based film, etc.) Fabric sheet composite products ( glass cloth / fluorine film, etc.) |

|

Coat or bond directly to the material while melting the hot-melt resin.

Realize high thickness coating or high precision applied through our orignal coating method (thickness accuracy within ± 2%)

Hot melt coating thickness from 150μm ~ 1000μm

Available for low-viscosity resin films when it can not be processed through extrusion method.

Excellent smoothness on coating surface

Direct coating available for various substrates

Examples of embossing

Examples of embossing

Embossing onto the film surface.

Embossing of 20μ~ several hundreds μ

Random mat processing and pattern embossed (Square, hexagonal, etc.) processing

Embossing process on both sides.

Water repellency imparted by embossing